PMMA, PS and Polycarbonate diffuser available; High efficiency and outstanding hiding; Dimension and light transmission can be customized;

PMMA, PS and Polycarbonate material available; Good glaring control, help achieve UGR<19 or 16; Various style can be available.

PMMA, PS and Polycarbonate material available; A good selection can be available; Welcome Co-development.

Light guide plate with highest uniformity and good light efficiency; Can make various size and shape; Can meet your budge demands with different technology and material.

0.125mm-0.5mm , PET and Polycarbonate material available; With diffusion or reflective function; Can be supplied by roll or cut to piece; Can be backed with adhesive and can fabricated into various shape.

Extrusion of Polycarbonate Profiles Diffuser in Clear, Opal and frosted surface; High efficiency and outstanding hiding ability; No public mold, private mold be welcomed.

Your Trusted LED Diffuser Sheets Partner

J.K. Optics combines more than a decade of expertise with cutting-edge manufacturing technology to produce high-performance Diffuser Sheets.

Utilizing advanced, dust-free co-extrusion processes and premium Japanese Mitsubishi raw materials, we ensure every product delivers superior light diffusion, exceptional durability, and consistent quality.

Our flexible OEM/ODM services enable precise customization to meet your unique design needs.

We offer a wide range of premium diffuser sheets products for wholesale purchase, as we are a renowned manufacturer.

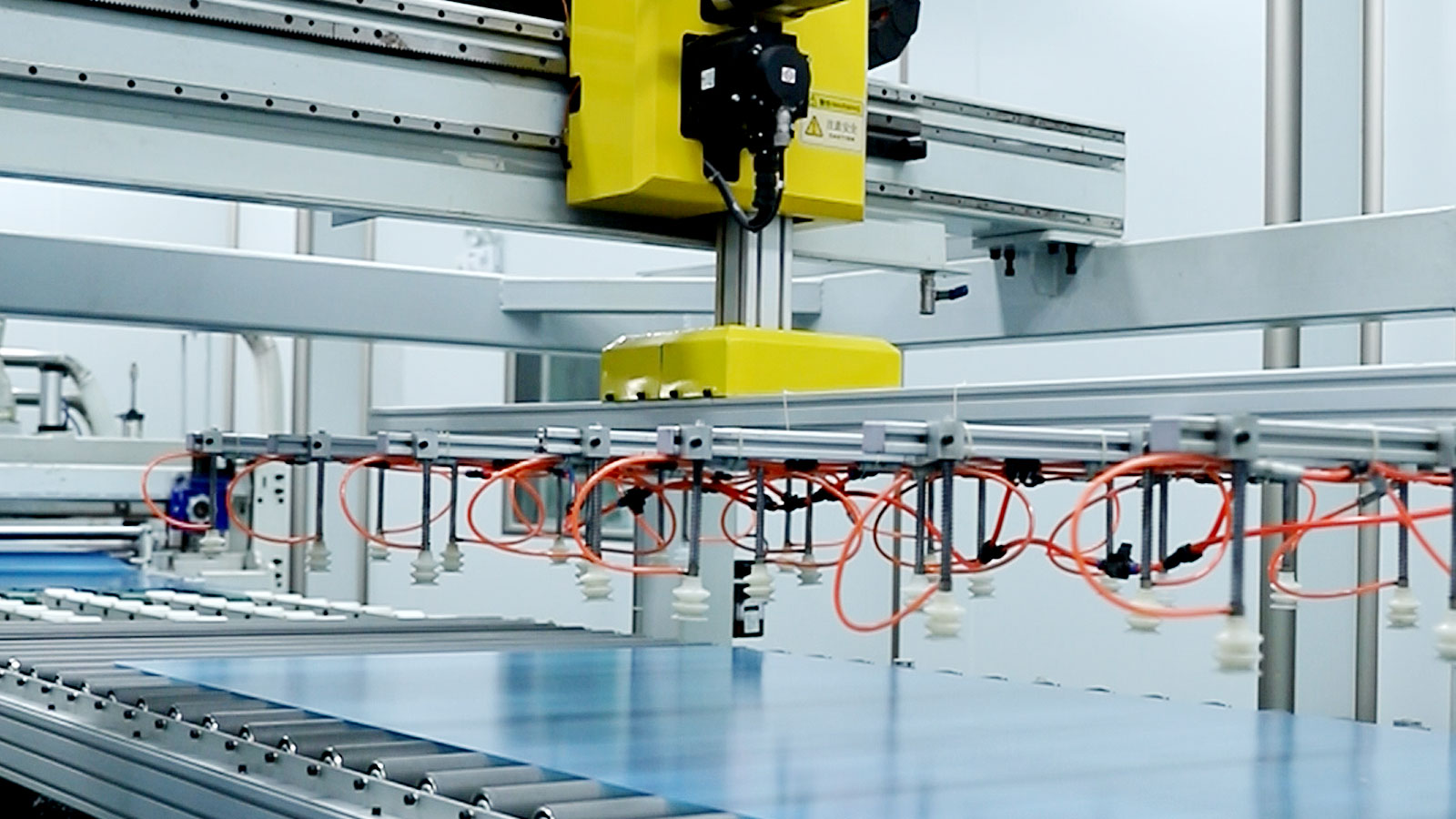

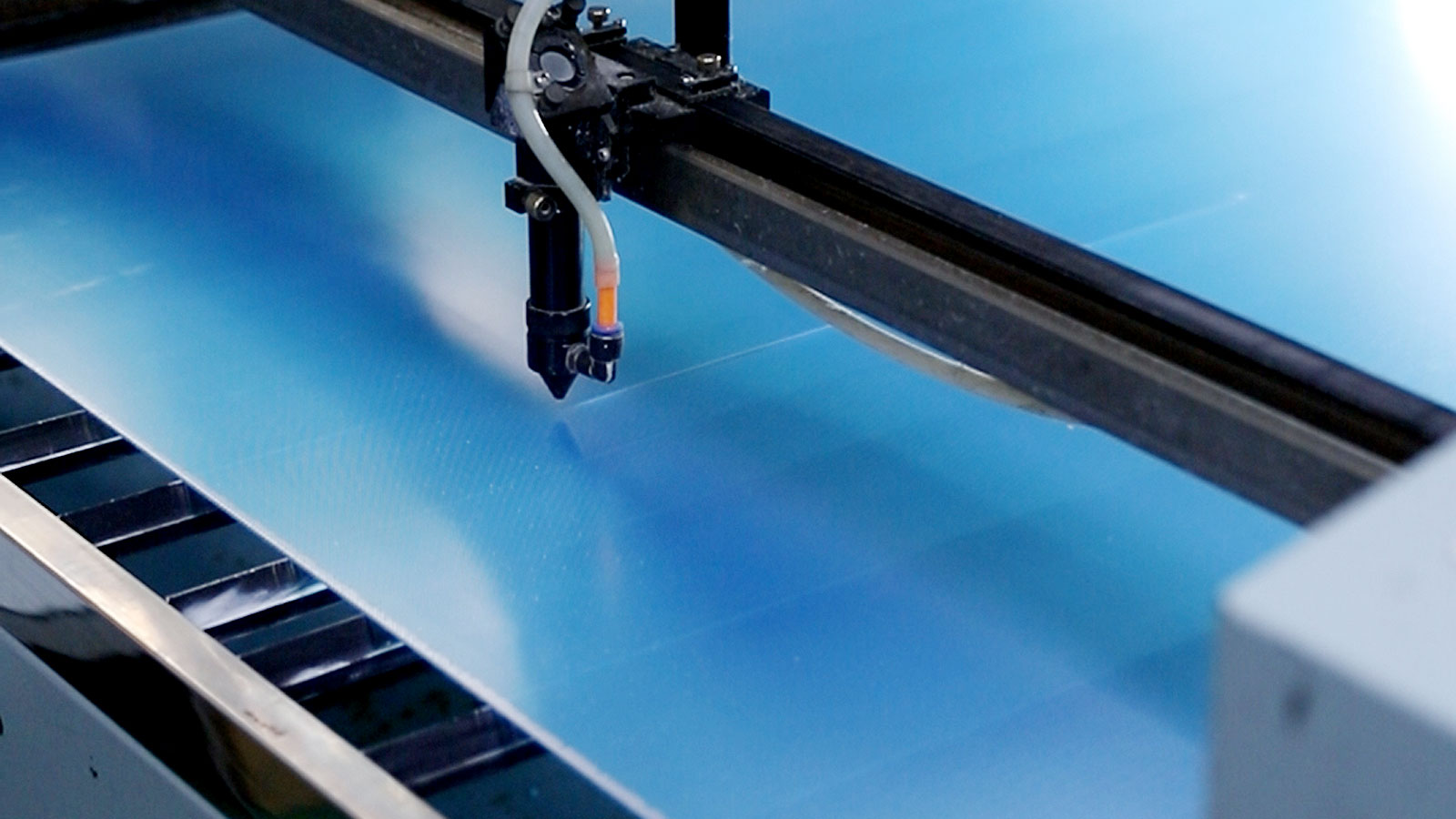

Our cutting-edge manufacturing process, featuring fully automated control systems and advanced equipment. Explore how our dust-free co-extrusion technology, combined with premium Japanese Mitsubishi raw materials, sets us apart in delivering high-performance LED diffuser sheets.

From global exhibitions to hands-on demos with top LED brands—our trade show highlights prove why J.K. Optics is the go-to partner for optical diffusion. Browse real-world snapshots of our team in action, showcasing cutting-edge diffuser solutions and collaborating with industry leaders. No hype—just the tangible expertise and innovation we bring to every project.

At J.K. Optics, our certifications stand as a testament to our unwavering commitment to quality, innovation, and reliability. Our rigorous standards and industry-recognized certifications ensure that every Diffuser Sheets solution meets the highest criteria for performance and safety.

Total factory area: 21,500 square meters

Total equipment: 207 sets

QC equipment: 23 sets

Engineering team: 225 engineers

QC team: 34 engineers

J.K. Optics engineers provide you with direct services;

Submit a project solution, and the analysis engineer will send you a report;

The process engineer will arrange your project accordingly;

Production Engineer is in charge of monitoring the whole process.

Self-inspection: When a diffuser sheets completes a process, operator A measures the it himself.

Mutual inspection: When the diffuser sheets go to the next step, Engineer B measures the it first and then works on it.

Professional Inspection: After all the processes, the professional QC team will inspect and check the handle thoroughly.

A: With our streamlined, fully automated production and a large on-hand inventory, most custom orders are delivered within 2-3 weeks, ensuring that your production lines stay on schedule.

A: Our dust-free co-extrusion process uses premium raw materials from Japanese Mitsubishi, combined with rigorous quality checks at every production stage to guarantee flawless, uniform light diffusion every time.

A: Absolutely. From bespoke small orders to a 600-ton monthly production capacity, our flexible manufacturing system is designed to meet both niche needs and high-volume demands without compromising quality.

A: We provide extensive OEM/ODM services including tailored thickness, texture, light transmission rates, and sizes, ensuring the diffuser sheets meet your specific design and functional requirements.

A: Yes, our dedicated technical support team works with your R&D and engineering teams from design through post-installation, offering 24/7 after-sales service to resolve any material or technical queries.

A: Through cutting-edge R&D and custom micro-prismatic textures, our diffuser sheets are engineered to minimize glare, enhance brightness uniformity, and ensure optimal light output even under challenging conditions.

A: Our unmatched product range, precision engineering, proven quality, and reliable logistics allow us to not only meet but exceed industry standards. We’re a partner committed to innovation and continuous improvement, ensuring you benefit from the latest advancements in LED diffusion technology.