We offer a wide range of premium Diffuser Sheet products for wholesale purchase, as we are a renowned manufacturer.

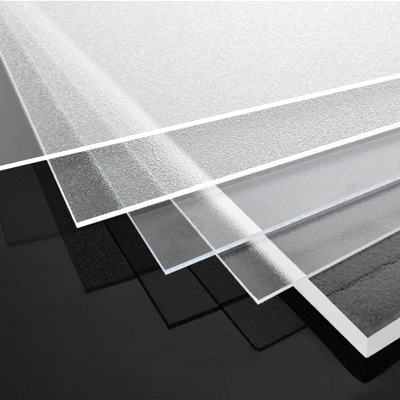

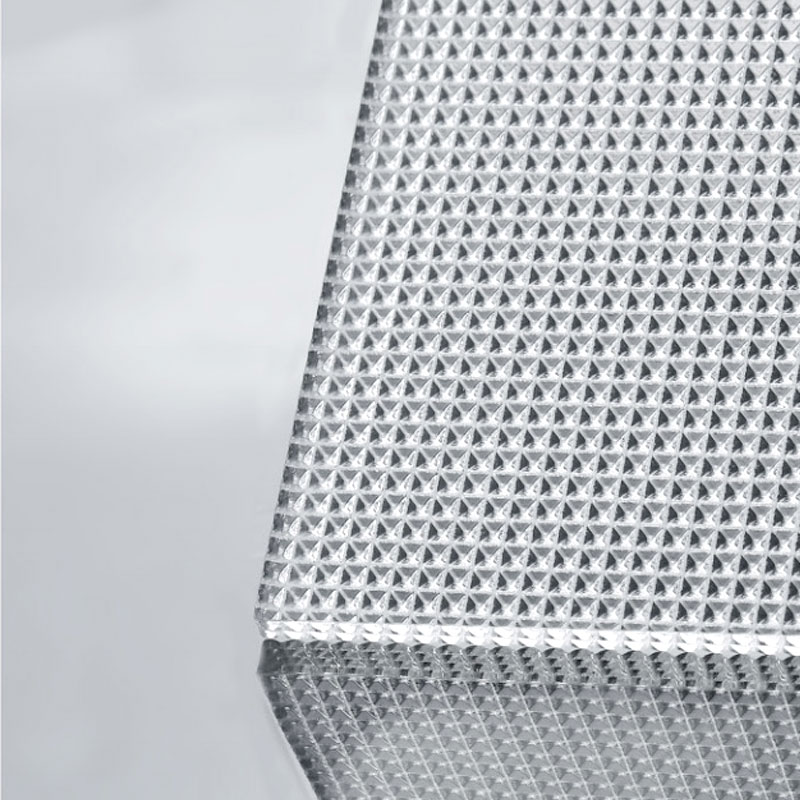

PMMA, PS and Polycarbonate diffuser available; High efficiency and outstanding hiding; Dimension and light transmission can be customized;

PMMA, PS and Polycarbonate material available; Good glaring control, help achieve UGR<19 or 16; Various style can be available.

PMMA, PS and Polycarbonate material available; A good selection can be available; Welcome Co-development.

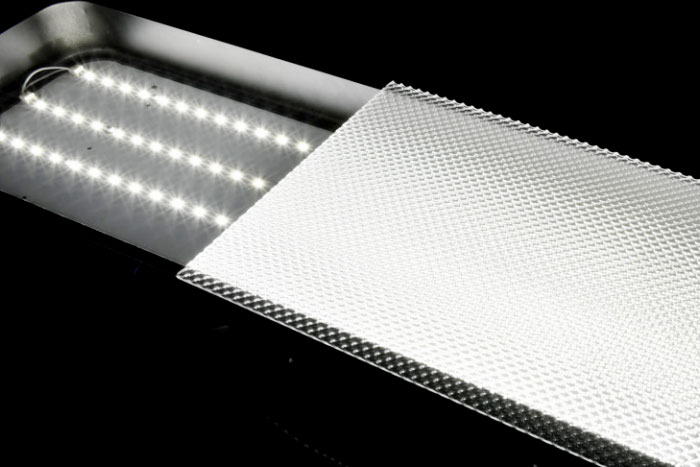

Light guide plate with highest uniformity and good light efficiency; Can make various size and shape; Can meet your budge demands with different technology and material.

0.125mm-0.5mm , PET and Polycarbonate material available; With diffusion or reflective function; Can be supplied by roll or cut to piece; Can be backed with adhesive and can fabricated into various shape.

Extrusion of Polycarbonate Profiles Diffuser in Clear, Opal and frosted surface; High efficiency and outstanding hiding ability; No public mold, private mold be welcomed.

J.K. Optics Diffuser Sheet Work Best for LED Lights

Focused on the producing of optical plastic sheet for lighting and decoration industry, being Committed to provide creative and professional products and solution to meet customer’s various requirements.

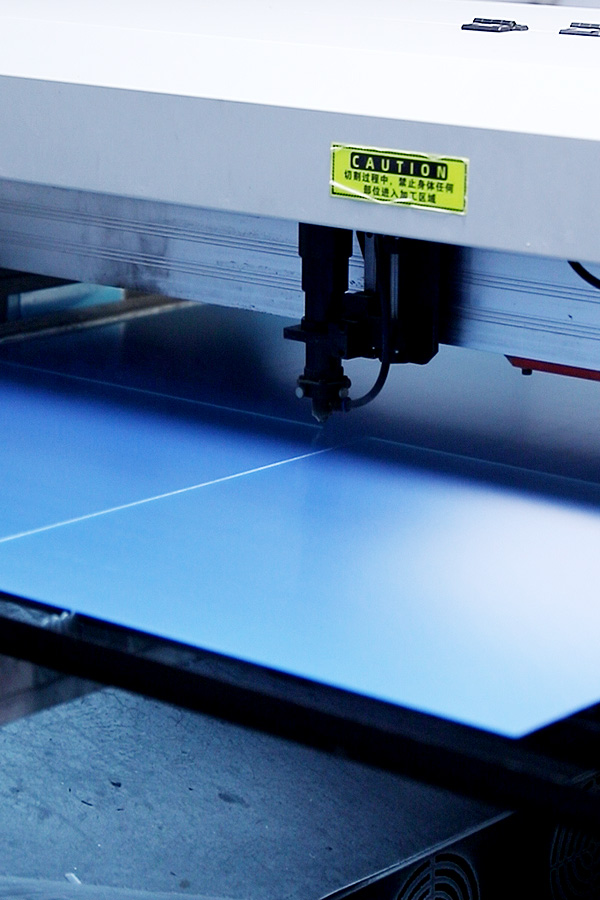

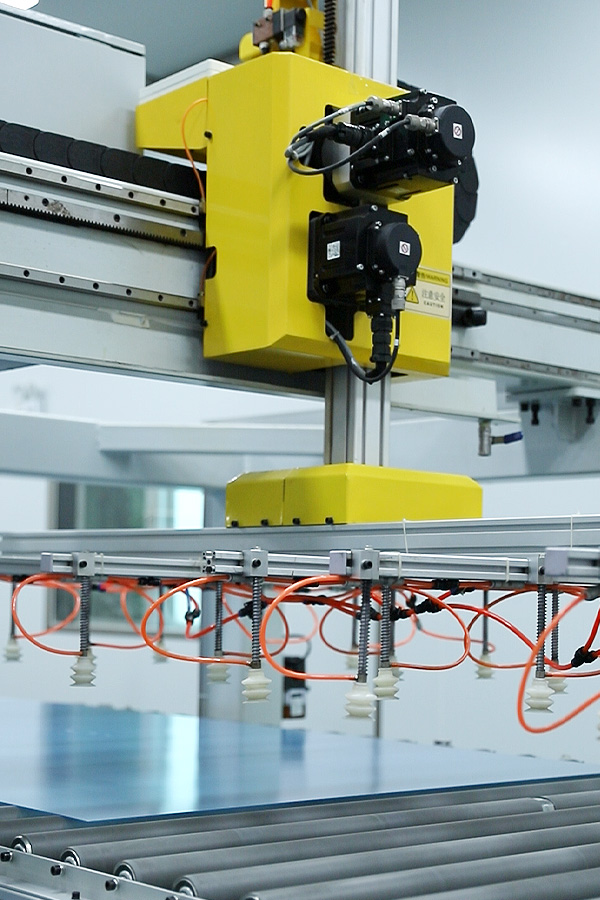

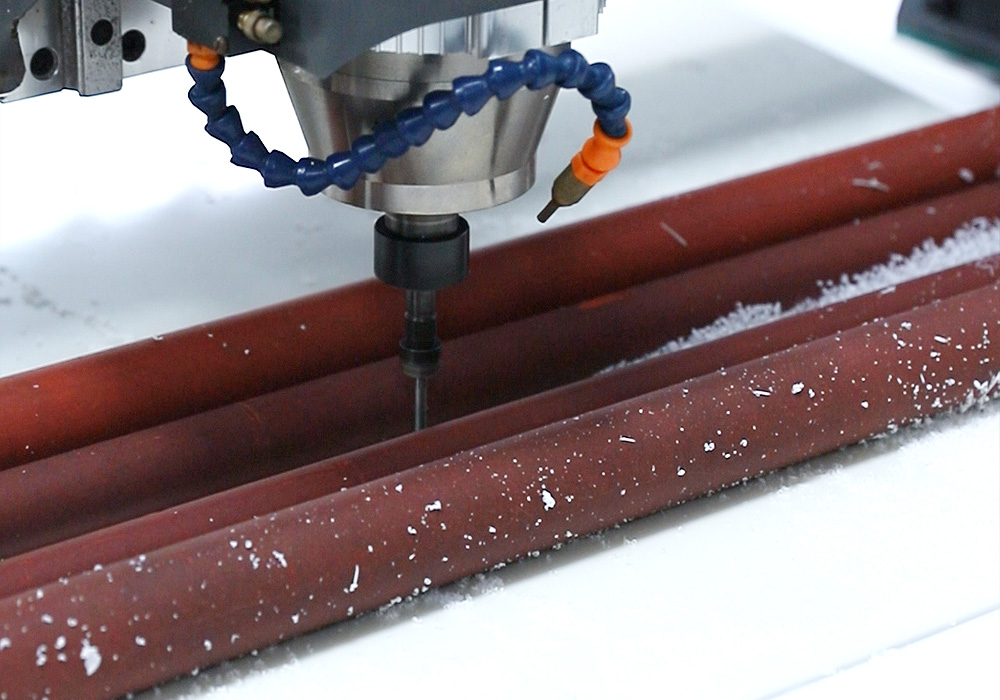

Plastic sheet manufacturer with strong fabricating ability, We have very extensive and diverse range of machinery to do the fabricating with exquisite technology.

Very wide and diverse range of products with advanced processing equipment and exquisite craftsmanship technicians, we can meet various demands from different customer.

Your Trusted LED Diffuser Sheet Partner

J.K. Optics combines more than a decade of expertise with cutting-edge manufacturing technology to produce high-performance Diffuser Sheet.

Utilizing advanced, dust-free co-extrusion processes and premium Japanese Mitsubishi raw materials, we ensure every product delivers superior light diffusion, exceptional durability, and consistent quality.

Our flexible OEM/ODM services enable precise customization to meet your unique design needs.

We support you to optimize your design to improve the performance and reduce the cost.

With 10 years of experience in Diffuser Sheet manufacturing and supplies

Custom Solutions, Timely Deliveries, and Uncompromising Quality for Global Leaders

Total factory area: 21,500 square meters

Total equipment: 207 sets

QC equipment: 23 sets

Engineering team: 225 engineers

QC team: 34 engineers

J.K. Optics engineers provide you with direct services;

Submit a project solution, and the analysis engineer will send you a report;

The process engineer will arrange your project accordingly;

Production Engineer is in charge of monitoring the whole process.

Self-inspection: When a diffuser sheets completes a process, operator A measures the it himself.

Mutual inspection: When the diffuser sheets go to the next step, Engineer B measures the it first and then works on it.

Professional Inspection: After all the processes, the professional QC team will inspect and check the handle thoroughly.

From global exhibitions to hands-on demos with top LED brands—our trade show highlights prove why J.K. Optics is the go-to partner for optical diffusion. Browse real-world snapshots of our team in action, showcasing cutting-edge diffuser solutions and collaborating with industry leaders. No hype—just the tangible expertise and innovation we bring to every project.

At J.K. Optics, our certifications stand as a testament to our unwavering commitment to quality, innovation, and reliability. Our rigorous standards and industry-recognized certifications ensure that every Diffuser Sheet solution meets the highest criteria for performance and safety.

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

We will start mass production after getting your approval and deposit, and we will handle the shipment.