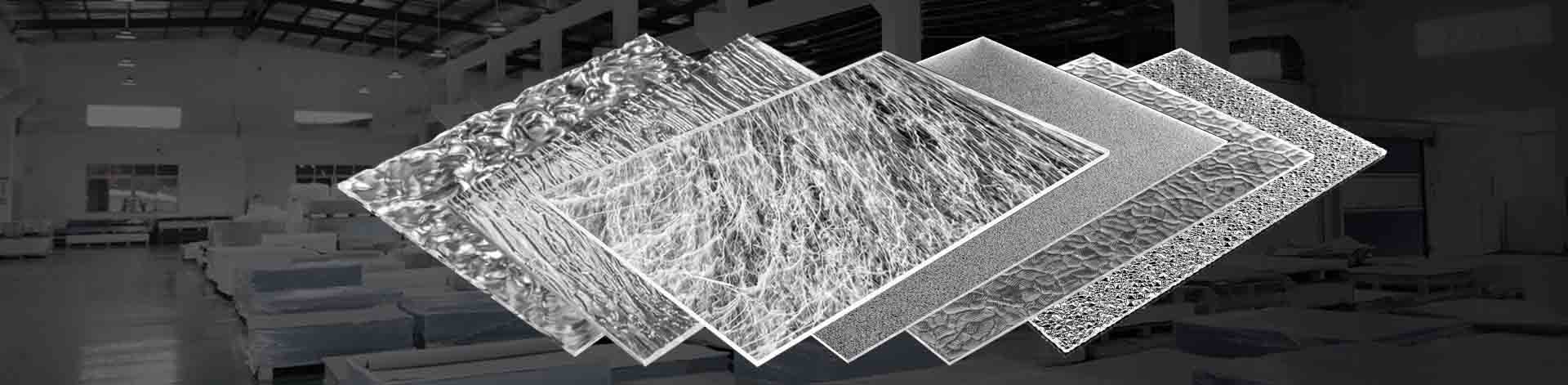

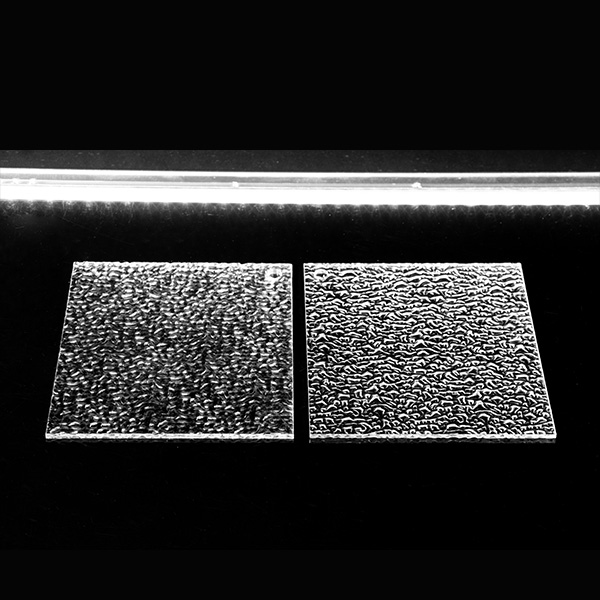

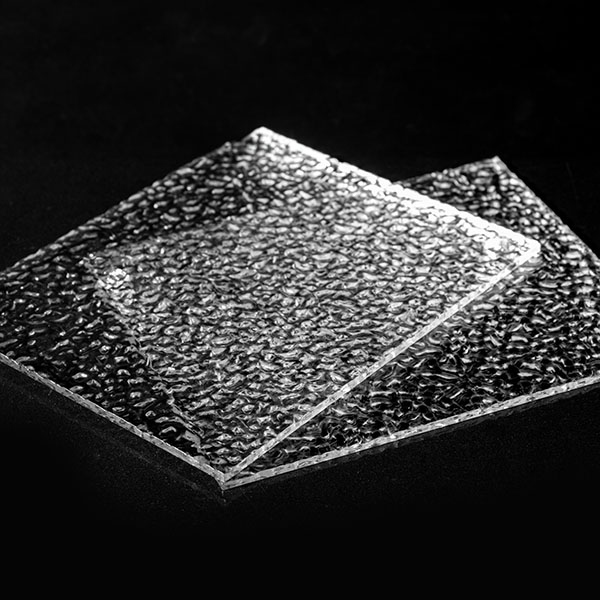

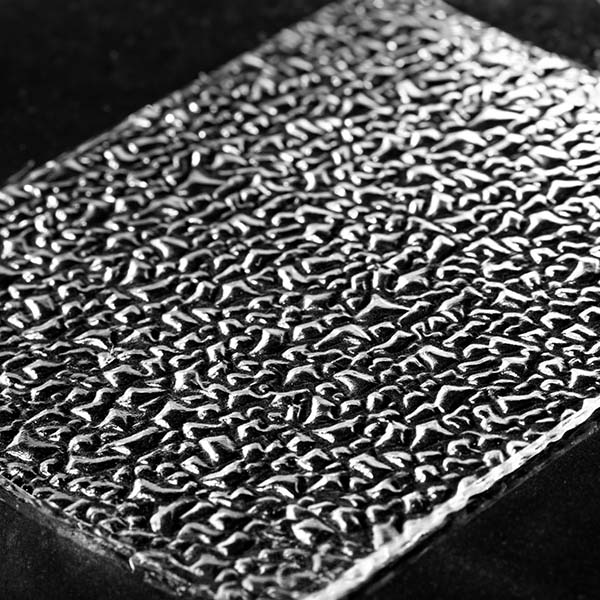

Rain Textured Acrylic Sheets is an innovative material that simulates natural rainfall texture on the surface of acrylic sheets through precision technology. It is both decorative and functional and is widely used in lighting, architecture, interior design and commercial display fields. Its unique optical effect and weather resistance make it an ideal choice for modern space design.

1. PMMA substrate: 100% new material polymethyl methacrylate is used, with a light transmittance of up to 92%, an impact strength 17 times that of glass, and a weight of only half that of glass.

2. Size and thickness

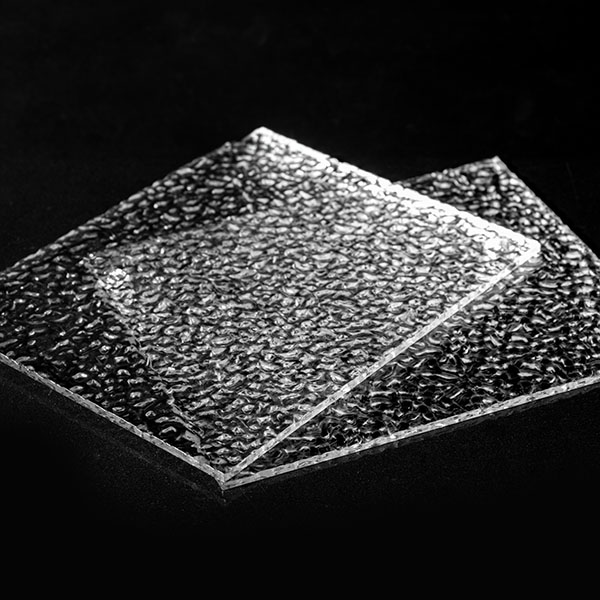

The standard size is 1250mm×2500mm, with a thickness range of 2.5mm-12.0mm, and supports customized cutting.

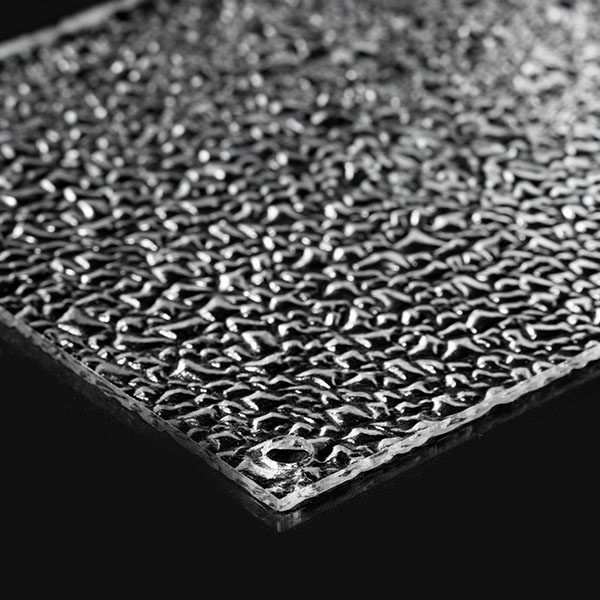

3. Light diffusion

The texture design makes the light scattering uniformity greater than 90%, eliminating dazzling spots, and is suitable for scenes such as LED light boxes and backlit signs.

4. Balance between light transmission and privacy

The light transmittance of 2.5mm thick sheets is about 85%, and the light transmittance of 12.0mm thick sheets is about 65%. The thickness can be selected according to needs.

5. Impact resistance

After the drop ball impact test (1kg steel ball, 1.2m high free fall), the sheet has no cracks or damage.

6. Weather resistance

After the QUV accelerated aging test (5000 hours), the yellowing index (ΔYI) is <3, and the transmittance attenuation is <5%, which is suitable for long-term outdoor use.

7. Chemical resistance

Resistant to acid and alkali solutions (pH 3-11), alcohol and common cleaning agents.

1. Lighting engineering

Light boxes and signs: 2.5mm thick sheets are used for ultra-thin light boxes, with light uniformity >85% and energy consumption reduced by 20%.

Art installations: 12.0mm thick sheets are used for large sculptures or interactive installations, with a load-bearing capacity of 50kg/m².

2. Interior decoration

Partitions and background walls: 6.0mm thick sheets are matched with LED light strips to create dynamic light and shadow effects and enhance the sense of space hierarchy.

Furniture panels: 3.0mm thick sheets are used for tabletops and cabinet doors, with both wear resistance and aesthetics, and a surface hardness of 2H.

3. Commercial displays

Display cabinets and display racks: 5.0mm thick sheets are used for jewelry and cosmetics display, with a balance of light transmittance and impact resistance to protect the safety of exhibits.

Interactive screens: Combined with touch technology, they are used for digital guides or advertising displays, with a response time of <10ms.

4. Building facades

Canopies and sunshades: 8.0mm thick sheets are used for outdoor shading structures, with a light transmittance of 70% and a 30% increase in thermal insulation performance.

Decorative curtain walls: 10.0mm thick sheets are used for building facades, with a wind pressure resistance of 12 levels, meeting the safety standards for high-rise buildings.

1. Daily cleaning

Use a soft brush or vacuum cleaner to remove dust, and wipe stubborn stains with warm water + neutral detergent (pH 6-8), avoiding the use of detergents containing alcohol or ammonia.

Fingerprints and oil stains can be wiped gently with a microfiber cloth dipped in isopropyl alcohol (concentration ≤70%).

2. Long-term maintenance

For outdoor use, it is recommended to add UV absorbers or choose UV-coated sheets to extend the service life.

Avoid contact with sharp objects. If necessary, apply a protective film (thickness 50-100μm).

3. Repair and replacement

Minor scratches can be polished with 2000-grit sandpaper. Deep scratches require replacement of the sheet.

Minor deformation can be corrected by heating (≤120℃). Severe deformation requires contacting the supplier for replacement.

Q: What is the maximum size?

A: The standard size is 1250mm×2500mm, and the maximum customizable size is 3050mm×2050mm.

Q: Is it compatible with LED light strips?

A: It supports compatibility with common LED light strips such as 3528, 5050, and 2835. It is recommended that the light strip spacing is ≤50mm.

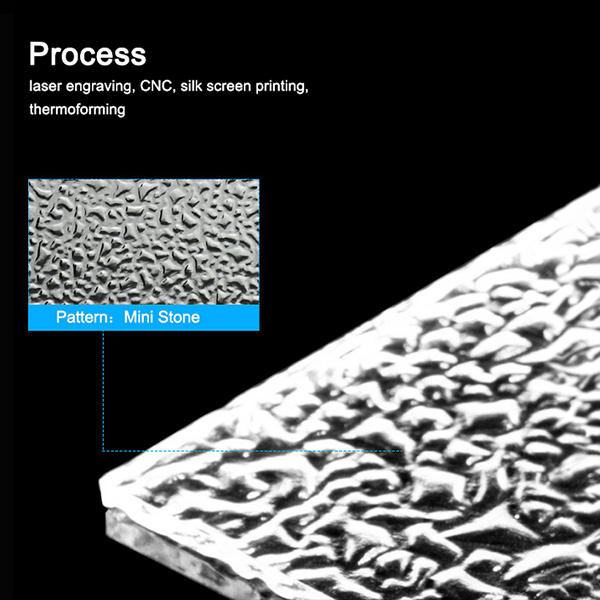

Q: How durable is the texture?

A: The texture is formed by UV curing or die casting process, with a wear resistance of 5H pencil hardness, and no falling off or deformation after 5 years of outdoor use.

Q: What is the fire rating?

A: It complies with UL94 V-0 flame retardant standard, self-extinguishing time from fire <5 seconds, smoke density ≤50.

Ingredients: |

1. PMMA |

2.PE protection film |

项目 Item | 试验法 Test Method | 单位 Unit | 亚克力板PMMA |

吸水率 water adsorption | ASTM D570-98 | % | 0.3 |

热变形温度 distortion temperature | ASTM D648-07 | ℃ | 88.0 |

维卡软化温度 vicat softening temperature | ASTM D1525-09 | ℃ | 104.0 |

线膨胀系数 linear expansivity | ASTMD696 | cm/℃ | 7.8*10-5cm |

热传导率 Thermal conductivity | ASTMD177 | cm*sec℃ | 4.5*10-4Cal |

弯曲强度 Bending Strength | ISO177 | MPa | 91.4~119 |

抗拉强度 Tensile Strength | ISO527 | MPa | 75 |

悬臂梁缺口冲击强度 Notched Izod Imapct Strength | ISO179 | KJ/M2 | 1.5 |

燃烧性 flammability | UL 94-1996 | HB |

4. Characteristics

1) Material characteristics

尺寸Dimension(L×W×T) | ||

长(L) | 宽(W) | 厚(T) |

1250mm | 2500mm | 3.0mm—20.0mm |

注:可根据客户不同模具需求,开好需要尺寸。 Note: according to customer demand for different mold, build the required size | ||