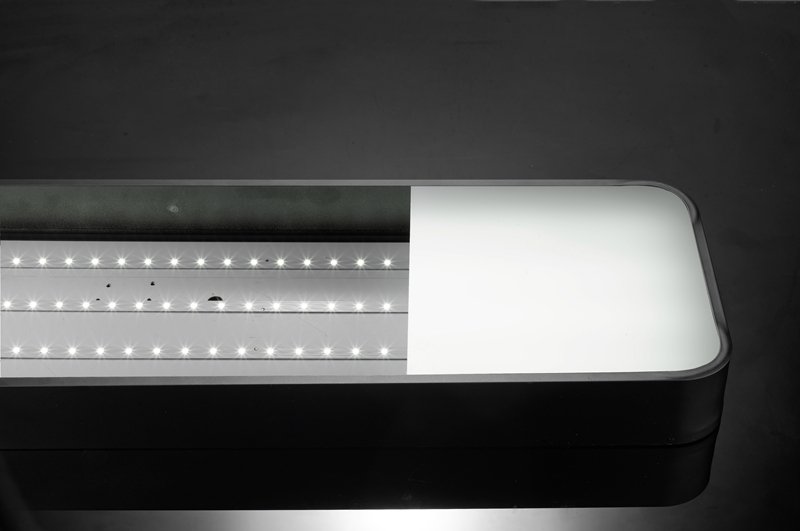

Acrylic Diffuser Plate is an optical lighting diffuser manufactured from optical-grade PMMA raw material through controlled formula processing and optimized surface texturing. From the user experience perspective, it delivers stable, visually comfortable illumination by balancing high light transmission with effective lamp concealment. When installed in LED lighting systems, the diffuser transforms concentrated light sources into evenly distributed surface illumination, reducing visual disturbance and maintaining consistent brightness perception. Its optical behavior supports long-term visual comfort by minimizing uneven luminance while preserving a clean and professional lighting appearance.

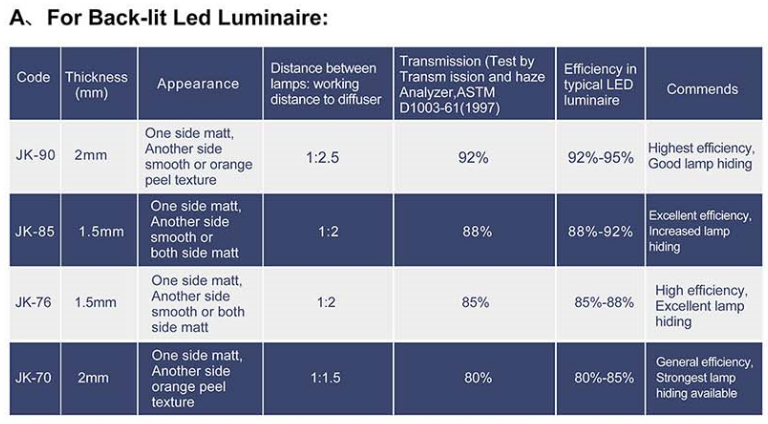

The diffuser plate provides light transmission levels ranging from 80 percent to 92 percent, measured according to ASTM D1003-61 standards for transmission and haze. Higher transmission options such as 92 percent at 2 mm thickness allow strong luminous output, while lower transmission levels improve lamp concealment. This controlled transmission range enables precise balancing between brightness and visual comfort, ensuring consistent illumination without exposing LED point sources.

Multiple surface appearances are available, including one side matte with the other side smooth, one side matte with orange peel texture, and double-side frosted. These surface structures directly influence light diffusion behavior by scattering incoming light at controlled angles. Matte and textured surfaces reduce direct lamp visibility, while smooth surfaces maintain stable light flow, enabling flexible optical tuning for different lighting system requirements.

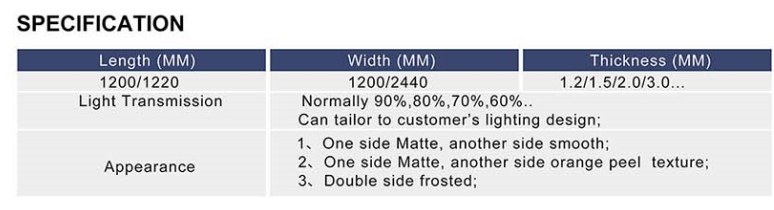

The diffuser plate is produced in thickness options such as 1.2 mm, 1.5 mm, 2.0 mm, 2.5 mm, and 3.0 mm, supporting precise control over diffusion strength and lamp hiding performance. Thinner panels maintain higher luminous efficiency, while thicker panels enhance diffusion and concealment. This precision allows designers to adjust optical performance without altering overall luminaire structure.

Performance data indicates lamp hiding efficiency between 80 percent and 95 percent, depending on thickness and surface configuration. For example, JK-90 at 2 mm thickness achieves 92–95 percent efficiency, delivering strong concealment while maintaining high brightness. This ensures LED sources remain visually shielded, preventing glare and localized brightness hotspots.

The acrylic diffuser plate is produced in standardized dimensions including 1200 × 1220 mm and 1200 × 2440 mm, ensuring compatibility with common LED luminaire systems. Controlled manufacturing processes maintain consistent thickness and optical uniformity across the entire sheet, preventing luminance variation and ensuring reliable performance in large lighting installations.

Acrylic Diffuser sheet are designed with different light diffusion to meet various fixture performance requirements.The distinct light diftusionlevels thatcan be matched with other design elements to help achieve thedesired lighting qualtes for different fixture designs. Usually there are back Iitand side lighting two kinds of led luminaire application:

In back-lit LED lighting systems, the acrylic diffuser plate operates at optimized lamp-to-diffuser distances such as 1:1.5 to 1:2.5, allowing balanced diffusion and high luminous efficiency. This configuration ensures uniform surface brightness while effectively concealing LED point sources across large panel areas.

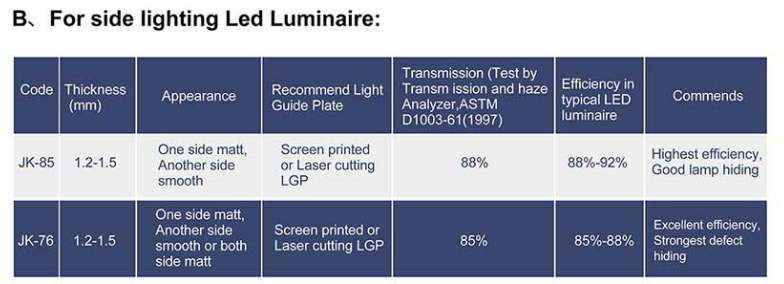

For side lighting LED luminaires, the diffuser integrates with screen-printed or laser-cut light guide plates. Transmission values between 85 percent and 88 percent support stable light extraction across the panel surface, improving defect hiding and maintaining consistent brightness along extended light paths.

In office lighting environments, the diffuser supports visually comfortable ambient illumination by reducing direct glare and balancing brightness levels. Its controlled diffusion improves visual clarity across workspaces, helping maintain focus during prolonged desk and screen-based tasks.

Within conference room lighting systems, the acrylic diffuser ensures even overhead illumination across tables and seating areas. The stable light distribution minimizes distracting reflections on screens and surfaces, supporting clear visual conditions during meetings and presentations.

In commercial interior lighting designs, the diffuser plate contributes to a uniform and orderly lighting appearance across ceiling panels and integrated luminaires. Controlled light diffusion prevents uneven brightness and enhances overall spatial visual consistency.

In institutional facilities such as training centers and public buildings, the diffuser supports standardized lighting performance through predictable transmission and lamp hiding behavior. Its optical stability ensures consistent illumination quality across multiple rooms and installations.

In architectural lighting applications, the acrylic diffuser plate supports continuous and uniform light lines. Its dimensional stability and surface consistency allow seamless integration into linear and panel-based lighting designs, maintaining visual continuity across large illuminated areas.