PMMA, PS and Polycarbonate diffuser available; High efficiency and outstanding hiding; Dimension and light transmission can be customized;

PMMA, PS and Polycarbonate material available; Good glaring control, help achieve UGR<19 or 16; Various style can be available.

PMMA, PS and Polycarbonate material available; A good selection can be available; Welcome Co-development.

Light guide plate with highest uniformity and good light efficiency; Can make various size and shape; Can meet your budge demands with different technology and material.

0.125mm-0.5mm , PET and Polycarbonate material available; With diffusion or reflective function; Can be supplied by roll or cut to piece; Can be backed with adhesive and can fabricated into various shape.

Extrusion of Polycarbonate Profiles Diffuser in Clear, Opal and frosted surface; High efficiency and outstanding hiding ability; No public mold, private mold be welcomed.

Your Trusted LED Optical Plastic Partner

J.K. Optics combines more than a decade of expertise with cutting-edge manufacturing technology to produce high-performance Optical Plastic.

Utilizing advanced, dust-free co-extrusion processes and premium Japanese Mitsubishi raw materials, we ensure every product delivers superior light diffusion, exceptional durability, and consistent quality.

Our flexible OEM/ODM services enable precise customization to meet your unique design needs.

We offer a wide range of premium Optical Plastic products for wholesale purchase, as we are a renowned manufacturer.

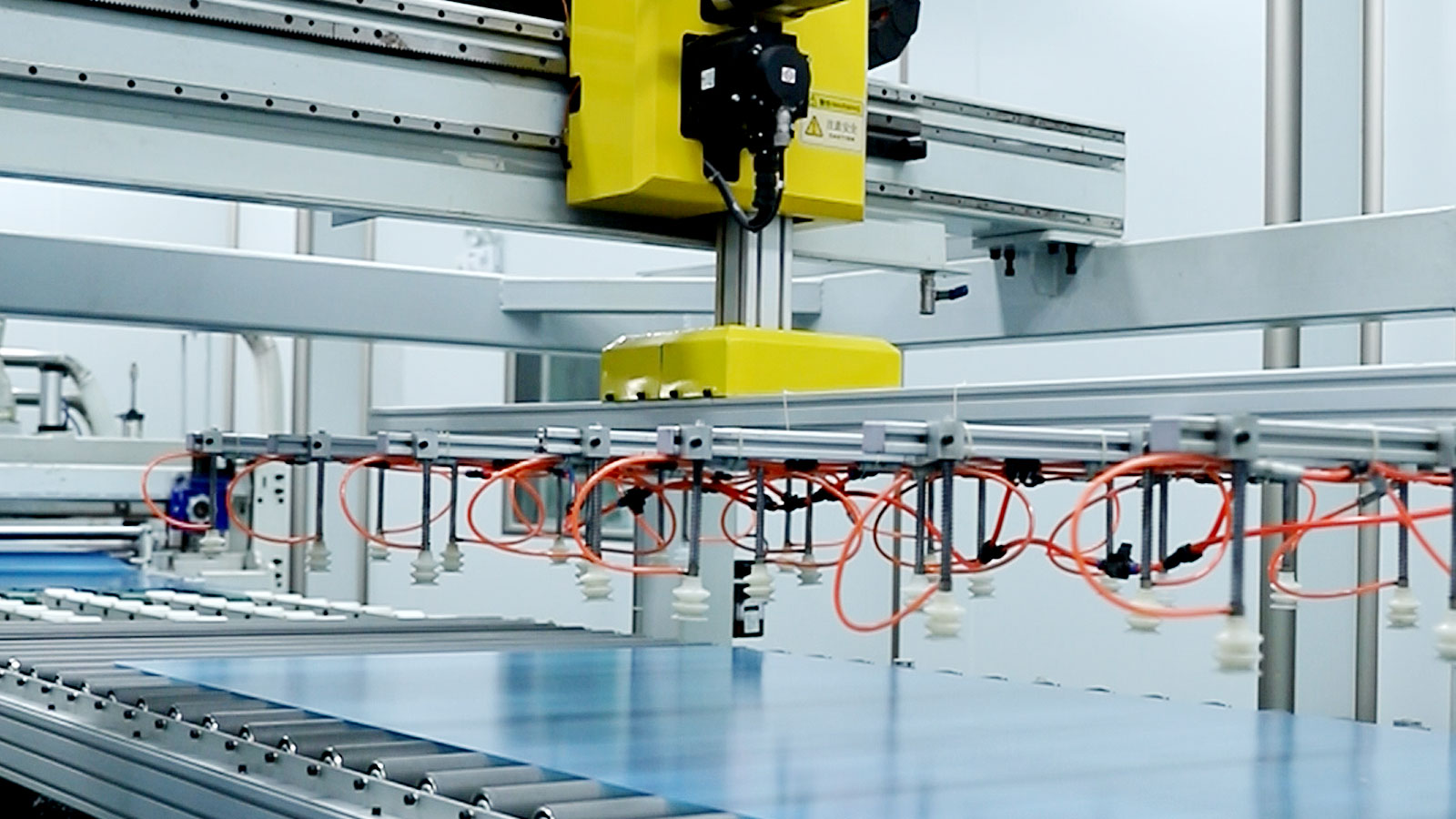

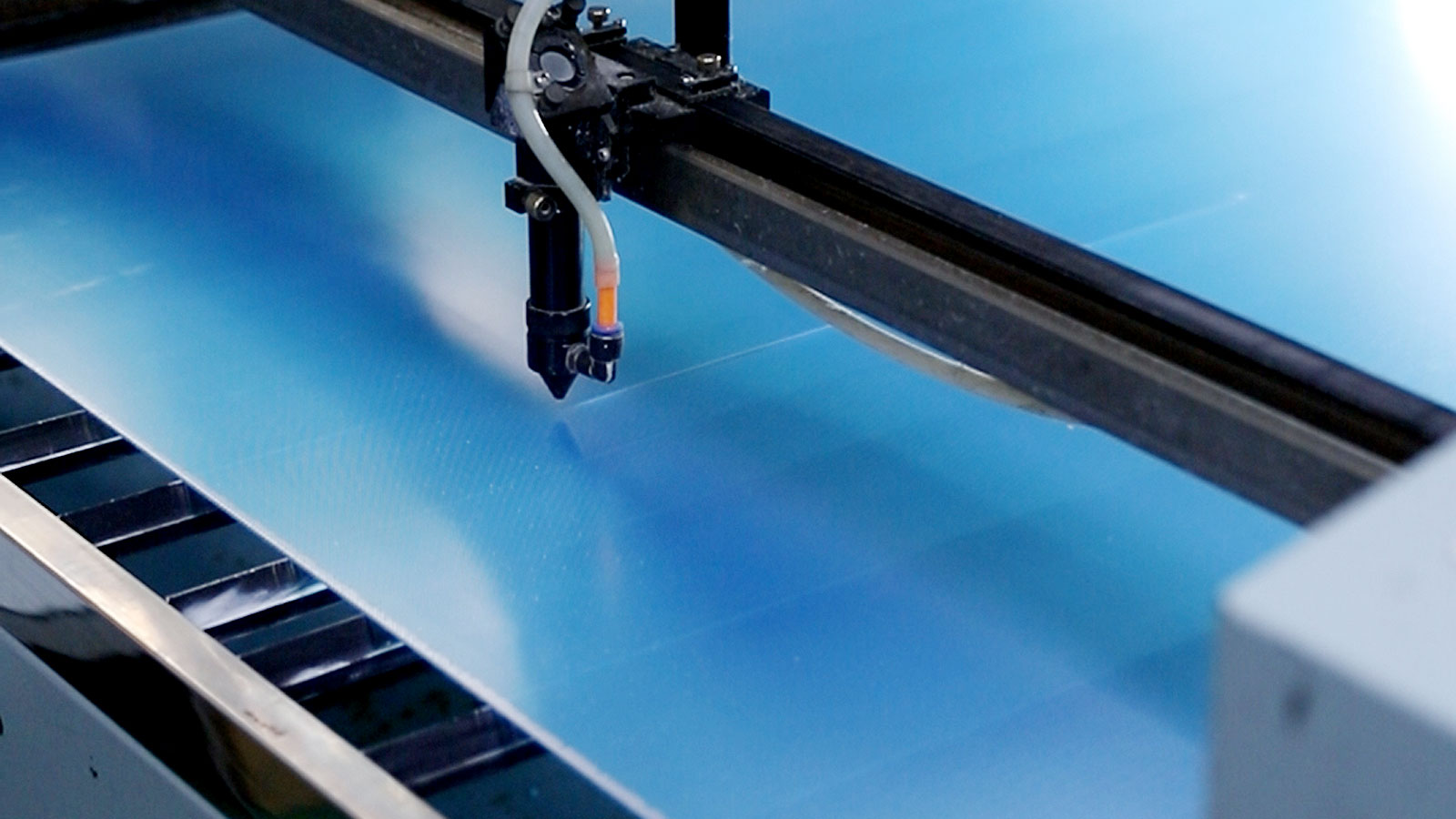

Our cutting-edge manufacturing process, featuring fully automated control systems and advanced equipment. Explore how our dust-free co-extrusion technology, combined with premium Japanese Mitsubishi raw materials, sets us apart in delivering high-performance LED Optical Plastic.

Welcome to our extensive range of Optical Plastic, which have been designed with care to meet the needs of various industries that require accuracy, transparency and resilience in their optical functions. Being a reputable manufacturer and supplier specializing in Optical Plastic, we are proud to provide advanced solutions that satisfy needs of our B2B consumers.

At KUNXIN, we comprehend that there is a significant role played by Optical Plastic in improving vision systems for different sectors. These include lenses, prisms, light guides and diffusers among others are just some of the applications covered by our range of Optical Plastic products. We manufacture our Optical Plastic using precision engineering techniques thereby ensuring unparalleled clarity as well as homogeneity which enables your product to exhibit superior optic performance.

Total factory area: 21,500 square meters

Total equipment: 207 sets

QC equipment: 23 sets

Engineering team: 225 engineers

QC team: 34 engineers

J.K. Optics engineers provide you with direct services;

Submit a project solution, and the analysis engineer will send you a report;

The process engineer will arrange your project accordingly;

Production Engineer is in charge of monitoring the whole process.

Self-inspection: When a Optical Plastic completes a process, operator A measures the it himself.

Mutual inspection: When the Optical Plastic go to the next step, Engineer B measures the it first and then works on it.

Professional Inspection: After all the processes, the professional QC team will inspect and check the handle thoroughly.

A: With our streamlined, fully automated production and a large on-hand inventory, most custom orders are delivered within 2-3 weeks, ensuring that your production lines stay on schedule.

A: Our dust-free co-extrusion process uses premium raw materials from Japanese Mitsubishi, combined with rigorous quality checks at every production stage to guarantee flawless, uniform light diffusion every time.

A: Absolutely. From bespoke small orders to a 600-ton monthly production capacity, our flexible manufacturing system is designed to meet both niche needs and high-volume demands without compromising quality.

A: We provide extensive OEM/ODM services including tailored thickness, texture, light transmission rates, and sizes, ensuring the diffuser sheets meet your specific design and functional requirements.

A: Yes, our dedicated technical support team works with your R&D and engineering teams from design through post-installation, offering 24/7 after-sales service to resolve any material or technical queries.

A: Through cutting-edge R&D and custom micro-prismatic textures, our diffuser sheets are engineered to minimize glare, enhance brightness uniformity, and ensure optimal light output even under challenging conditions.

A: Our unmatched product range, precision engineering, proven quality, and reliable logistics allow us to not only meet but exceed industry standards. We’re a partner committed to innovation and continuous improvement, ensuring you benefit from the latest advancements in LED diffusion technology.