Polycarbonate Lighting Diffuser is an extruded optical diffuser sheet produced from optical-grade polycarbonate resin using controlled formula processing and surface texturing. From the user’s visual experience perspective, it delivers stable, uniform illumination while maintaining a clean and comfortable lighting appearance. The diffuser balances light transmission with effective lamp concealment, allowing LED and fluorescent light sources to appear evenly distributed rather than visually intrusive. Its controlled optical behavior supports consistent brightness perception across illuminated surfaces, helping users experience visually calm and orderly lighting conditions over long periods of exposure.

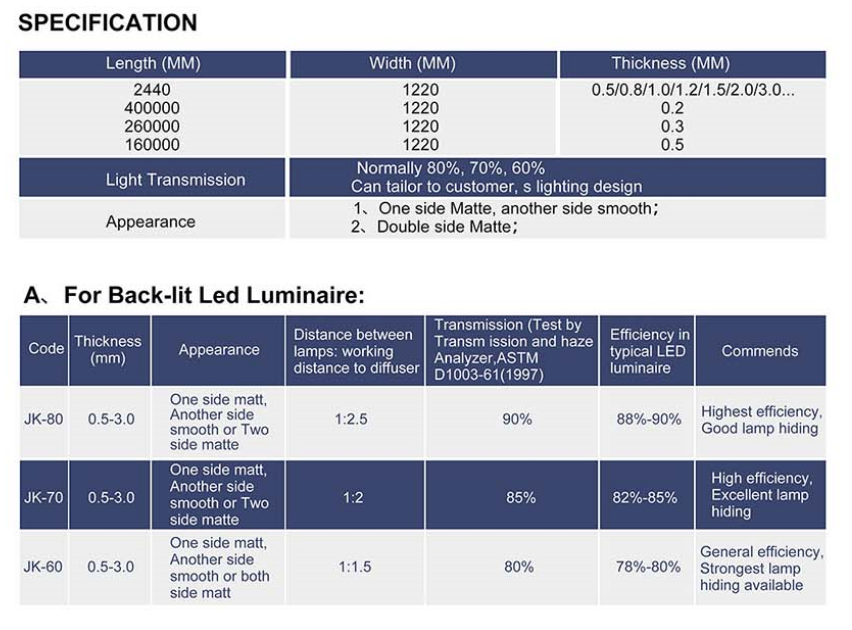

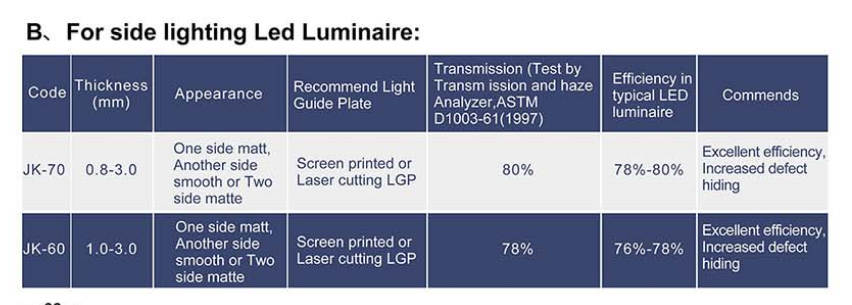

The diffuser offers selectable light transmission levels of 80 percent, 70 percent, and 60 percent, allowing controlled luminous output based on lighting design requirements. These values are measured through standardized transmission and haze analysis methods, ensuring predictable optical performance. Higher transmission options support brighter illumination, while lower transmission enhances lamp hiding capability. This balance allows designers to achieve uniform brightness without exposing LED point sources, maintaining consistent visual comfort across large lighting panels.

Manufactured from optical-grade polycarbonate, the diffuser provides stable optical performance combined with mechanical durability. Thickness options include 0.2 mm, 0.3 mm, and 0.5 mm, supporting consistent light diffusion behavior at different structural levels. The extruded polycarbonate structure maintains surface integrity and optical uniformity, ensuring that light diffusion characteristics remain consistent throughout prolonged operation in lighting systems.

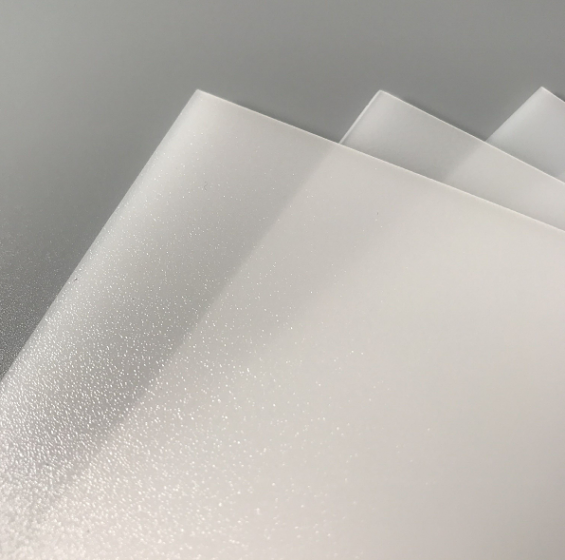

The diffuser supports two surface appearance configurations: one side matte with the other side smooth, or double-side matte. The matte surface reduces direct lamp visibility by scattering incoming light, while the smooth surface maintains controlled light flow. This surface flexibility allows precise tuning of diffusion strength without altering material composition, ensuring stable optical results across different luminaire designs.

Performance data shows lamp hiding efficiency ranging from 78 percent to 90 percent, depending on thickness and configuration. For back-lit luminaires, models such as JK-80 at 0.5–3.0 mm thickness achieve up to 90 percent transmission with 88–90 percent efficiency, offering strong lamp concealment while maintaining high luminous output. This ensures LED sources remain visually shielded, preventing glare and hotspot formation.

The diffuser is produced in standardized dimensions including 2440 mm, 4000 mm, 26000 mm, and 16000 mm lengths, with a consistent 1220 mm width. These standardized formats support compatibility with large-scale lighting installations and continuous lighting systems. Precision extrusion ensures uniform thickness and optical performance across the entire sheet, minimizing brightness variation and alignment issues during installation.

Acrylic Diffuser sheet are designed with diferent light diffusion to meet various fixture performancerequirements. The distinct light diffusion levels that can be matched with other design elements to helpachieve the desired lighting qualities for different fixture designs. Usually there are back-lit and sidelighting two kinds of led luminaire application:

In back-lit LED lighting systems, the diffuser is positioned at optimized lamp-to-diffuser distances such as 1:1.5 to 1:2.5, enabling balanced diffusion and lamp concealment. This spacing supports luminous efficiency between 78 percent and 90 percent, ensuring uniform panel brightness while effectively hiding LED point sources across large illuminated surfaces.

For side lighting LED luminaires, the diffuser integrates with screen-printed or laser-cut light guide plates. Transmission levels of 78 percent to 80 percent support controlled light extraction across the panel surface, improving defect hiding and reducing visible brightness inconsistencies along the light path.

In engineering and public infrastructure lighting systems, the polycarbonate diffuser supports stable illumination under continuous operation. Its consistent optical performance and standardized dimensions allow reliable light distribution across extended installations, ensuring uniform brightness and visual clarity in technically demanding environments.

In office lighting applications, the diffuser contributes to visually comfortable ambient illumination by limiting direct glare and balancing brightness levels. Controlled diffusion and lamp hiding performance help reduce visual fatigue during prolonged desk work while maintaining sufficient illuminance for professional tasks.

Within commercial interior lighting designs, the diffuser ensures consistent light appearance across ceiling panels and integrated lighting systems. Uniform diffusion prevents localized brightness peaks, supporting a clean and professional visual environment suitable for public and commercial spaces.

In public transportation interiors, such as rail or metro vehicles, the diffuser provides even illumination across cabins. Controlled glare reduction and stable light distribution improve passenger visual comfort while maintaining sufficient brightness for safety and visibility.

For large-area lighting installations, the diffuser’s long-length production capability allows continuous lighting lines with minimal joints. This supports uniform illumination across expansive spaces, reducing visual discontinuities and ensuring consistent optical performance throughout the installation.