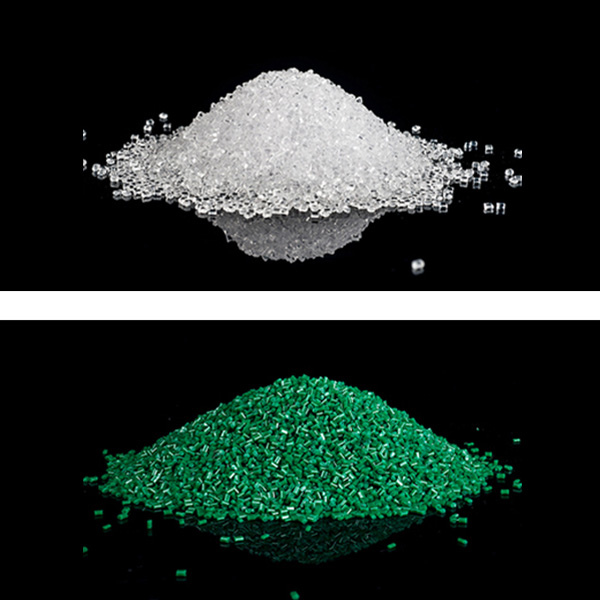

White Diffuser Sheet is mainly made of high molecular weight polycarbonate (PC) or acrylic (PMMA), with a common thickness range of 0.5mm to 3mm. It is a high-performance lighting light diffusion material with a milky white translucent sheet appearance, a smooth and delicate surface, and a uniform structure.

White Diffuser Sheet has excellent light diffusion efficiency, and its light diffusion rate can reach 88%-92%. It can effectively shield LED point light sources, achieve a soft and uniform surface light source effect, and significantly improve the lighting quality.

While achieving strong diffusion, White Diffuser Sheet can still maintain good light transmittance, with a light transmittance of usually 65%-85%. It provides a variety of light transmittance parameter options according to the application scenario, taking into account brightness and light blocking.

White Diffuser Sheet has excellent UV resistance and anti-aging ability. It can still maintain color stability and physical strength in outdoor strong light exposure or high humidity environment, and its service life is more than 5 years.

White Diffuser Sheet uses imported PC raw materials, and its impact strength is 250 times that of ordinary glass. It has high toughness and bending resistance, is suitable for coil cutting and large-area installation, and is safer to transport and use.

Depending on the different raw material formulas, it can achieve UL94 V-2 to V-0 flame retardant performance, and is widely used in commercial and industrial lighting systems with strict fire protection requirements to ensure safe use.

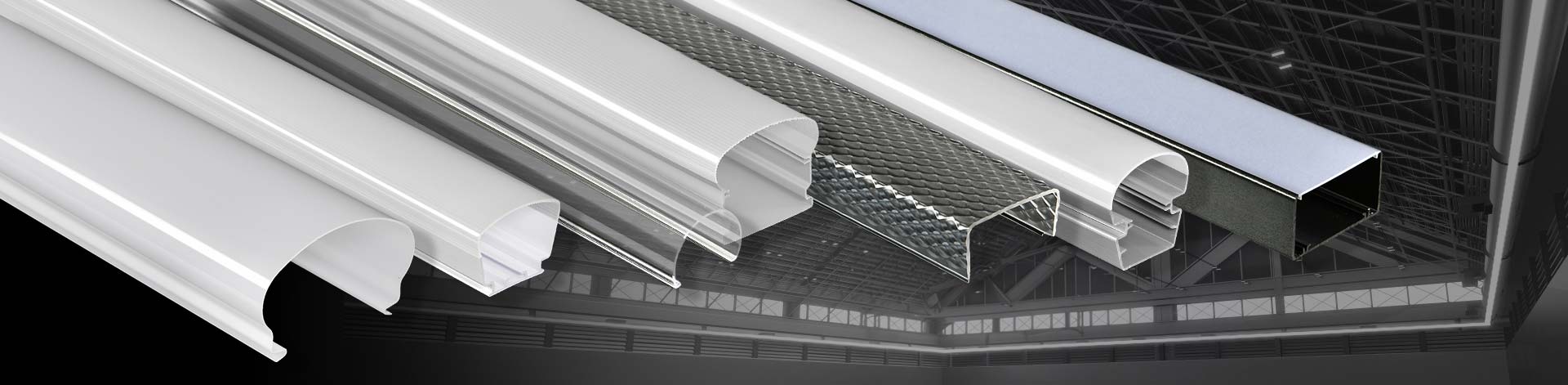

In LED flat panel lights and grille lights in shopping malls, hotels and office buildings, White Diffuser Sheet is used to evenly diffuse the light source, eliminate light spots, and make the space lighting softer and more balanced.

In places such as hospital operating rooms and laboratories that have extremely high requirements for lighting quality, White Diffuser Sheet improves visual comfort with its no stray light and low glare characteristics, ensuring the accuracy and safety of medical lighting.

In advertising light boxes at transportation hubs such as airports and subways, White Diffuser Sheet is used with LED modules to achieve uniform lighting effects, avoid dark areas and hot spots, and improve advertising readability.

In products such as smart light strips and ceiling downlights, it effectively integrates light as a diffuser cover to enhance the aesthetics and user experience of smart lighting products. It is often used in customized projects for brands such as Philips and Xiaomi.

In explosion-proof lamps in high-intensity environments such as factories and storage areas, the use of White Diffuser Sheet not only enhances the strength of the lamp body, but also maintains stable optical performance under high or low temperature conditions, ensuring clear lighting in the operating area.