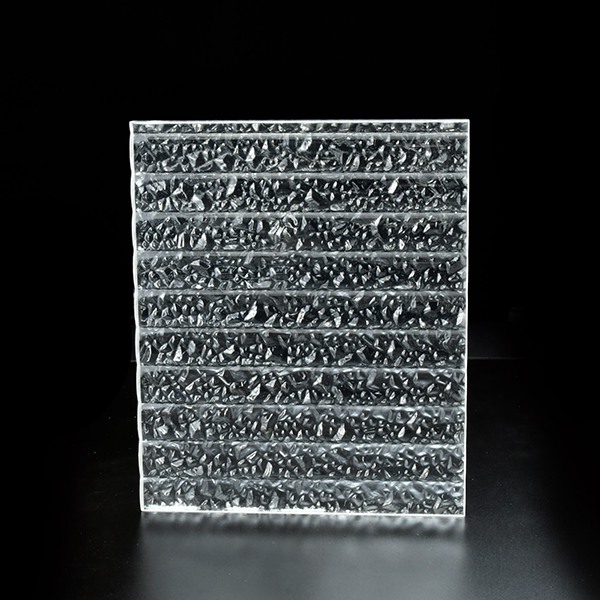

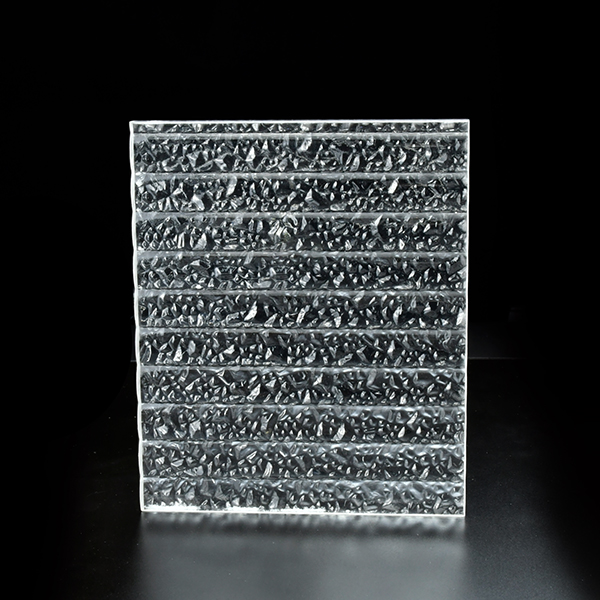

Ice Acrylic Sheet is a specially processed organic glass sheet named for its unique translucent ice crystal visual effect. This material combines the excellent properties of traditional acrylic sheets with stunning aesthetic performance, and is becoming increasingly popular in modern architectural decoration, display design and commercial space.

From the perspective of chemical composition, Ice Acrylic Sheet belongs to PMMA, but its surface is specially treated to form a fine concave and convex texture, which can refract light to produce an effect similar to ice crystals or frosted glass. Compared with ordinary acrylic sheets, Ice Acrylic Sheet is more artistic and high-end, while retaining the characteristics of acrylic materials such as lightness, durability and easy processing.

100% virgin material for easy processing

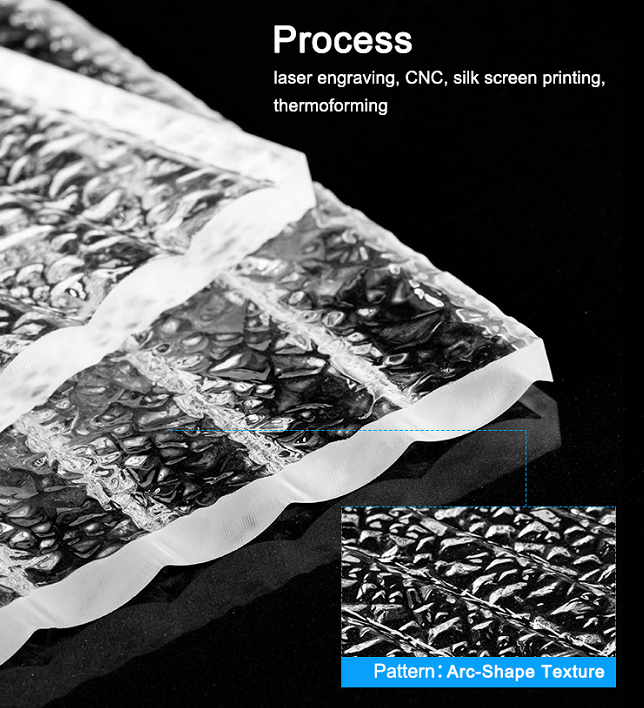

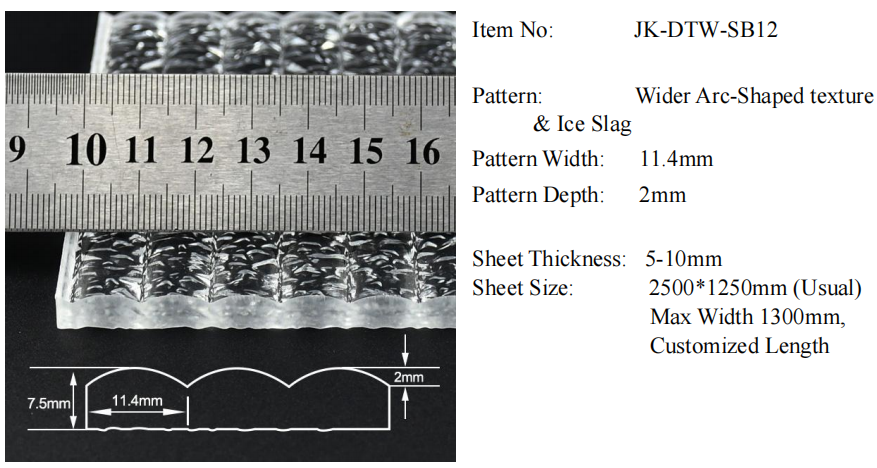

100% pure PMMA, excellent transparency, excellent aging resistance and chemical stability, good insulation and processing, suitable for laser engraving, CNC, silk screen, thermoforming, etc.

Lightweight

Ice Acrylic Sheet weighs less than half of glass

Excellent optical properties

Ice Acrylic Sheet has a light transmittance of more than 92%, which is better than ordinary glass. Its surface micro-texture structure can soften light, eliminate glare, and create a uniform and soft lighting effect.

Excellent weather resistance

High-quality Ice Acrylic Sheet contains UV stabilizers, which can resist the damage of ultraviolet rays in the sun, and will not show obvious yellowing and embrittlement after long-term use.

Safe and impact-resistant

The impact strength of Ice Acrylic Sheet is more than 10 times that of ordinary glass. When broken, it forms larger blunt-angle fragments instead of sharp fragments, which greatly reduces the risk of personal injury.

Color diversity

The product provides transparent, translucent and various color options, including solid colors, gradient effects and customized pattern printing. Good color stability, not easy to fade after long-term use.

Flame retardant performance

No toxic gas will be produced when exposed to fire. The burning speed is slow and it will extinguish itself when away from the fire, which meets the requirements of most building fire protection regulations.

Commercial space design field

High-end retail stores: Ice Acrylic Sheet has become the preferred decorative material for high-end retail spaces such as luxury stores, jewelry stores, and watch stores. Its unique ice crystal effect can create a hazy and noble display atmosphere for the product while maintaining sufficient light transmittance.

Commercial lighting system: As a diffusion material for LED panel lights, Ice Acrylic Sheet can produce a more uniform and softer light effect than ordinary acrylic.

Brand image wall: Ice Acrylic Sheet is used on the corporate logo wall and the background wall of the reception desk, and the backlight design can create a highly recognizable visual image.

Architectural decoration field

Office space partition: Modern open office spaces widely use Ice Acrylic Sheet to make translucent partitions, which not only ensures the clarity of space division, but also maintains a sense of visual connectivity.

Hotel and catering space: Michelin-star restaurants and VIP rooms of five-star hotels often use Ice Acrylic Sheet to make screens, wall decorations or chandelier covers to create a private and elegant dining atmosphere.

Bathroom space application: Bathroom partitions and washbasin water retaining plates use Ice Acrylic Sheet, which is both functional and beautiful. Its non-absorbent properties ensure long-term stability in humid environments.

Exhibition field

Museum showcase: The display of light-sensitive cultural relics requires strict control of light intensity, and the uniform diffuse reflection characteristics of Ice Acrylic Sheet make it an ideal choice.

Exhibition booths: 3 mm thick Ice Acrylic Sheet is light and easy to transport and install. At the same time, corporate logos can be customized through silk screen printing, UV printing and other technologies, making it a popular construction material for major exhibition centers.

Sales display props: Ice Acrylic Sheet is often used to make cosmetic counter test bottles, jewelry display stands, etc. Its anti-fingerprint properties reduce daily maintenance costs.

Home decoration field

Modern style partitions: Ice Acrylic Sheet is used to make entrance partitions and soft partitions between living rooms and dining rooms in small-sized houses, which not only ensures lighting but also divides functional areas.

Creative chandeliers and lamps: Brand lamps use Ice Acrylic Sheet to make lampshades in large quantities to achieve a unique diffuse light effect, becoming a new hot spot in the field of home lighting.

Bathroom accessories: Ice Acrylic Sheet is used in bathroom mirror frames, shelves, etc., which are both moisture-resistant and beautiful.

Special application scenarios

Medical environment: Due to its antibacterial and easy-to-clean properties, Ice Acrylic Sheet is used in hospital guide systems, nurse station partitions, etc.

Transportation: Ice Acrylic Sheet is used in the interior panels of high-speed rail carriages and aircraft cabins, which are both lightweight and safe.

Agricultural application: Special agricultural greenhouses use UV-resistant Ice Acrylic Sheet as a covering material to optimize light distribution.

1. Basic cleaning steps

Use a soft and clean feather duster to gently remove surface dust every week

Wipe with a slightly damp microfiber cloth every month

Stubborn stains can be treated with a neutral detergent (pH 6-8) diluted and treated

Finally, use a dry microfiber cloth to wipe the surface water stains

2. Recommended professional cleaners

Special acrylic cleaners

Isopropyl alcohol (70% concentration) is suitable for greasy stains

A 3:1 mixture of distilled water and white vinegar is suitable for scale

3. Tool selection recommendations

Prohibited: Hard cleaning tools such as steel wool and scouring pads

Recommended: Soft sponges, microfiber cloths

Soft-bristled long-handled mops can be used for large area cleaning

Ingredients: |

1. PMMA |

2.PE protection film |

项目 Item | 试验法 Test Method | 单位 Unit | 亚克力板PMMA |

吸水率 water adsorption | ASTM D570-98 | % | 0.3 |

热变形温度 distortion temperature | ASTM D648-07 | ℃ | 88.0 |

维卡软化温度 vicat softening temperature | ASTM D1525-09 | ℃ | 104.0 |

线膨胀系数 linear expansivity | ASTMD696 | cm/℃ | 7.8*10-5cm |

热传导率 Thermal conductivity | ASTMD177 | cm*sec℃ | 4.5*10-4Cal |

弯曲强度 Bending Strength | ISO177 | MPa | 91.4~119 |

抗拉强度 Tensile Strength | ISO527 | MPa | 75 |

悬臂梁缺口冲击强度 Notched Izod Imapct Strength | ISO179 | KJ/M2 | 1.5 |

燃烧性 flammability | UL 94-1996 | HB |

尺寸Dimension(L×W×T) | ||

长(L) | 宽(W) | 厚(T) |

1250/1220mm | 2500/2440mm | 5.0mm—12.0mm |

注:可根据客户不同模具需求,开好需要尺寸。 Note: according to customer demand for different mold, build the required size | ||