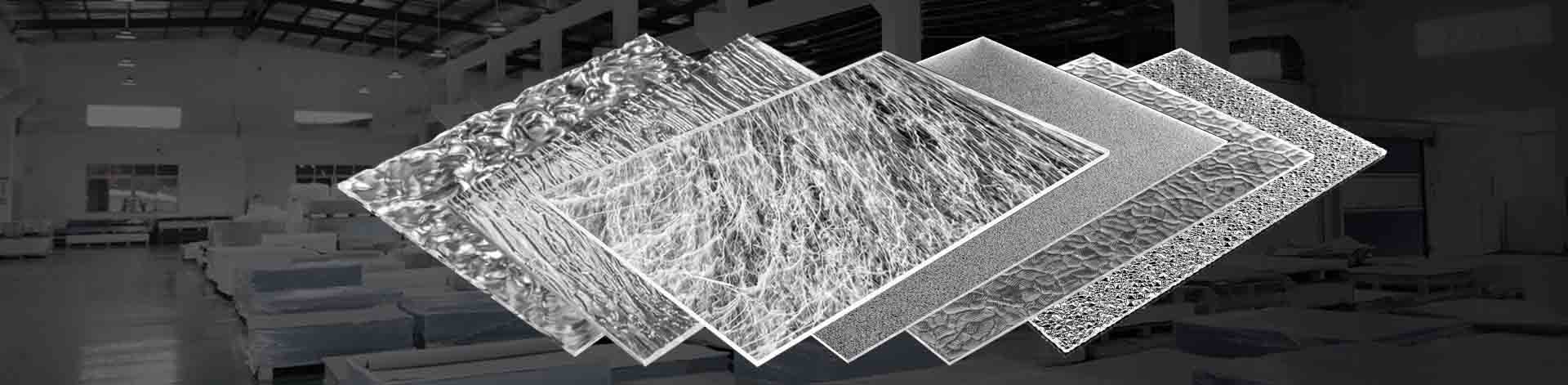

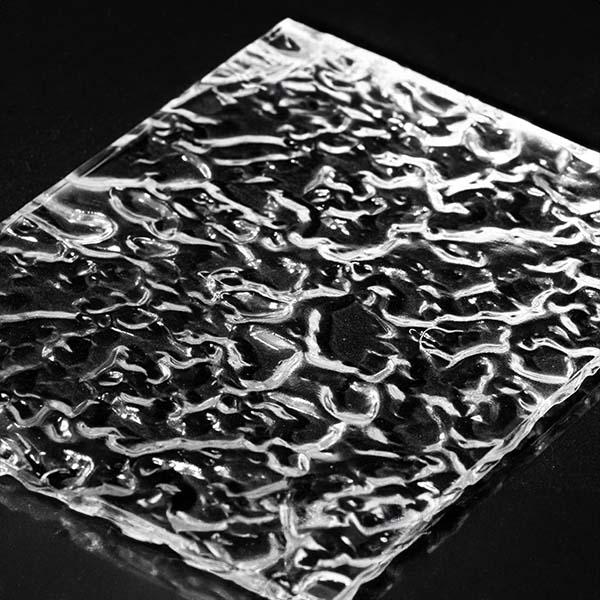

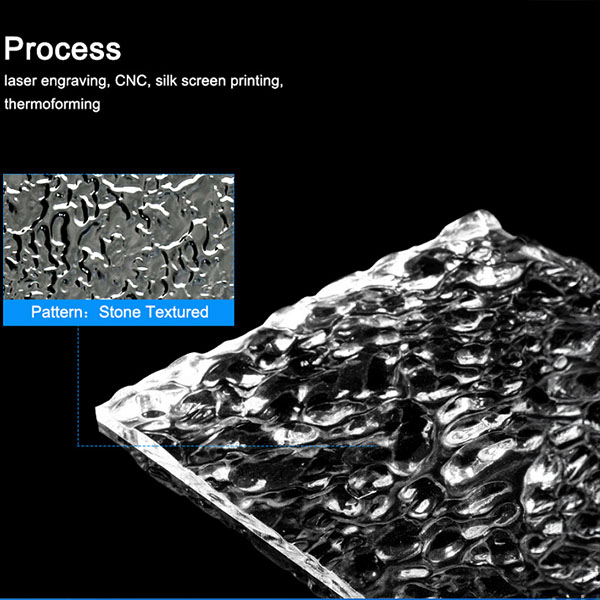

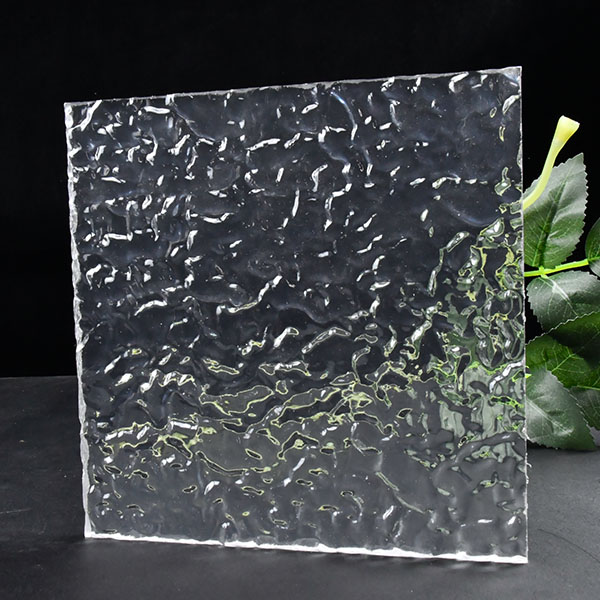

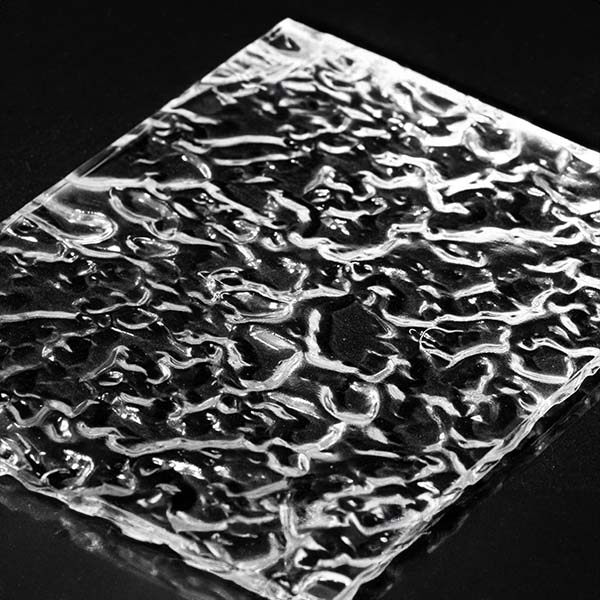

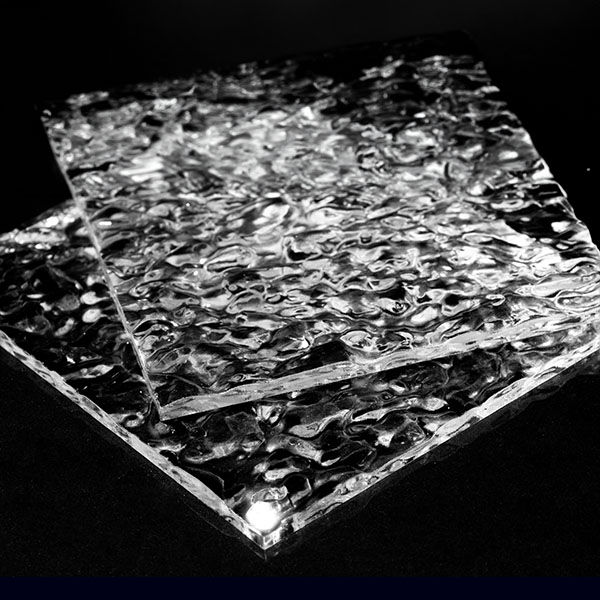

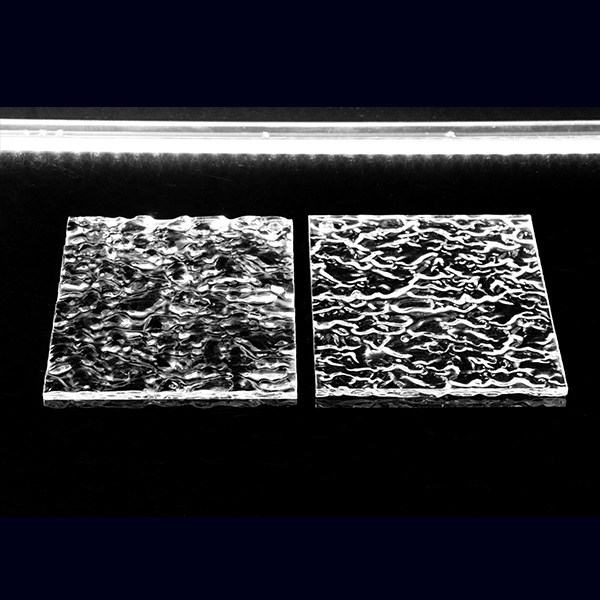

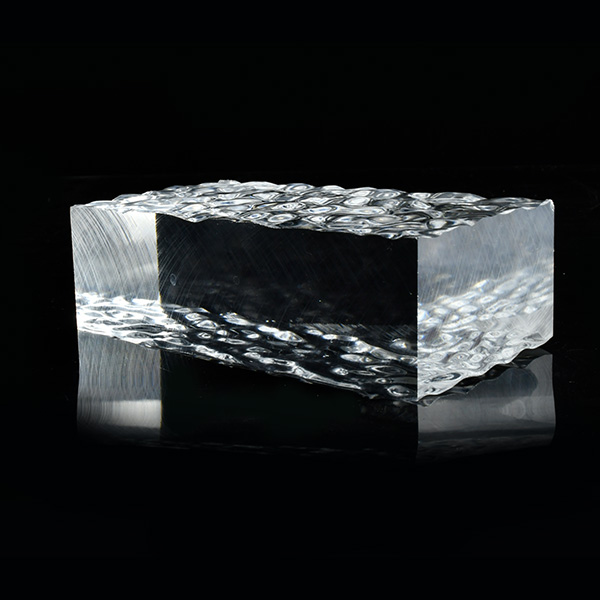

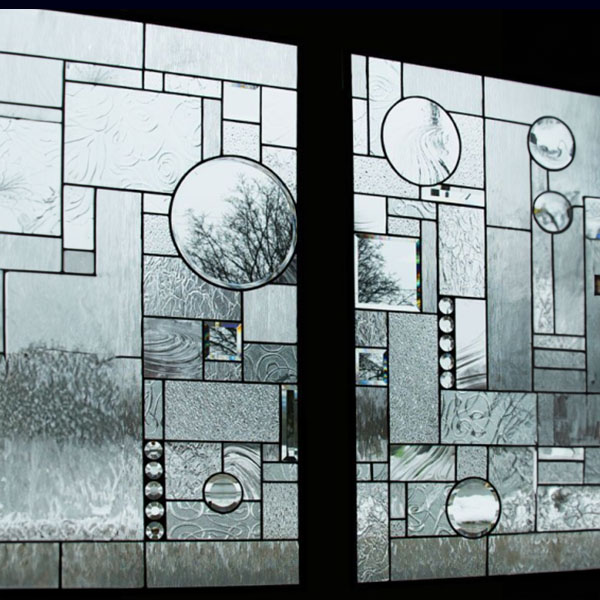

Attractively pattern, looks Stone texture, clear and produce certain light obstruction effect, it’s a great choice to bring interesting and beautiful patterns to partition , shower doors, display indoor/outdoor furniture, and home furnishing products.Architectural & Decorative applications, ideally instead of Rainbow glass & Decorative glass”

100% Virgin PMMA, Excellent Clear, outstanding aging resistance and chemical stability, good insulation and processability,suitable for laser engraving,CNC, Silk Printing, thermoforming and so on.

Crystal clear, Looks attractively transparent, but with certain light obstruction, bring kind of visual enjoyable

Impact resistance,Not easily broken, more safety than glass

Acrylic weighs less than half of that of glass

Textured & Patterned acrylic sheet are widely utilized in exterior architectural building, interior decoration including flooring, store fixtures, house division, furniture, displays, shower doors, cabinet and so on

Ingredients: |

1. PMMA |

2.PE protection film |

项目 Item | 试验法 Test Method | 单位 Unit | 亚克力板PMMA |

吸水率 water adsorption | ASTM D570-98 | % | 0.3 |

热变形温度 distortion temperature | ASTM D648-07 | ℃ | 88.0 |

维卡软化温度 vicat softening temperature | ASTM D1525-09 | ℃ | 104.0 |

线膨胀系数 linear expansivity | ASTMD696 | cm/℃ | 7.8*10-5cm |

热传导率 Thermal conductivity | ASTMD177 | cm*sec℃ | 4.5*10-4Cal |

弯曲强度 Bending Strength | ISO177 | MPa | 91.4~119 |

抗拉强度 Tensile Strength | ISO527 | MPa | 75 |

悬臂梁缺口冲击强度 Notched Izod Imapct Strength | ISO179 | KJ/M2 | 1.5 |

燃烧性 flammability | UL 94-1996 | HB |

尺寸Dimension(L×W×T) | ||

长(L) | 宽(W) | 厚(T) |

1220/1250mm | 2440/2500mm | 5.0mm—20.0mm |

注:可根据客户不同模具需求,开好需要尺寸。 Note: according to customer demand for different mold, build the required size | ||