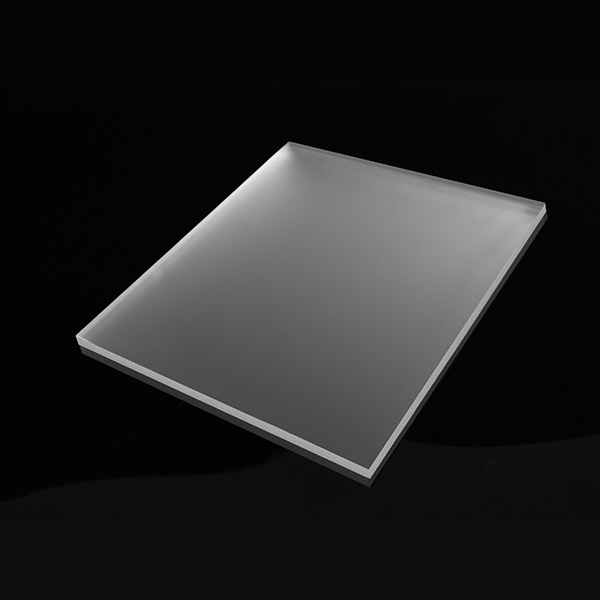

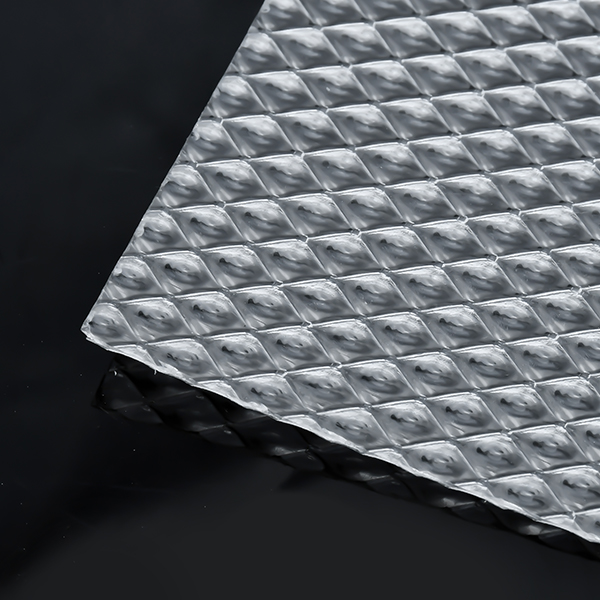

Large Frosted Acrylic Sheet is a sheet that uses a special process to treat the surface of a transparent acrylic sheet into a frosted effect. It has both the high transparency of acrylic materials and the diffuse reflection characteristics of frosted textures. Its size can be customized (maximum specifications up to 2050mm×3050mm), thickness range 1.8mm-50mm, widely used in architectural decoration, advertising display, industrial design and other fields, replacing traditional glass or plastic sheets.

Density: 1.2g/cm³.

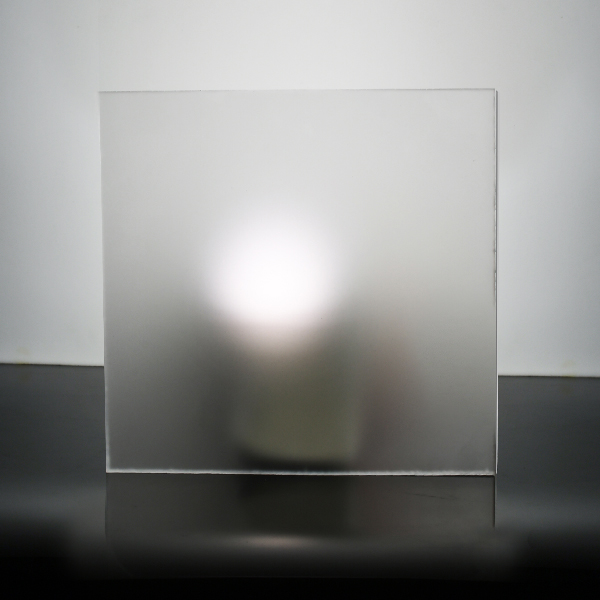

Transmittance: The transmittance of a single-sided frosted sheet is about 60%-70%, and the transmittance of a double-sided frosted sheet is about 40%-50%.

Thickness range: 1.8mm-50mm (conventional thickness 2mm, 3mm, 5mm, 8mm, 10mm).

Size range: standard size 1220mm×2440mm, maximum custom size 2050mm×3050mm.

Shrinkage: <0.4%.

Temperature range: -40℃ to 80℃.

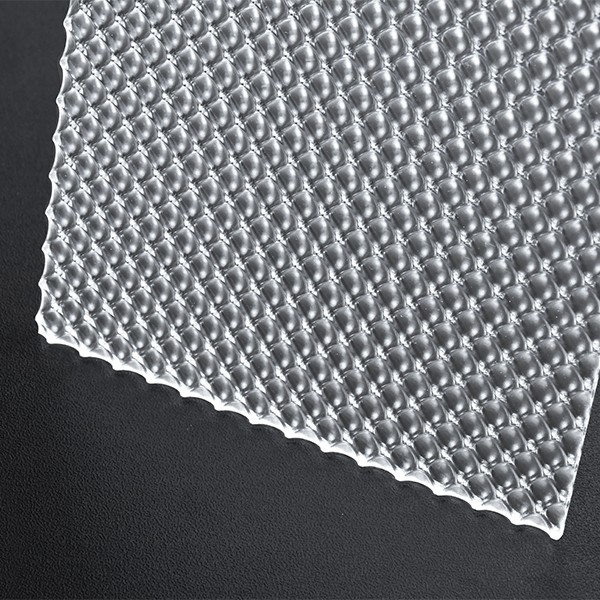

1. Optical performance:

The frosted surface achieves diffuse reflection, reduces glare, and improves light uniformity by 30%.

Supports customized colors (such as white, black, red, green, etc.), and the color difference ΔE ≤ 1.5 (CIELAB standard).

2. Mechanical properties:

Tensile strength 81-130MPa, bending strength 110-120MPa, and impact strength is 200 times that of ordinary glass.

Thickness tolerance ≤ ± 0.1mm, surface flatness ≤ 0.2mm/m.

3. Weather resistance:

Excellent UV resistance, light transmittance retention rate ≥ 85% after 5 years of outdoor use, color difference ΔE ≤ 3.

Chemical corrosion resistance (no damage to pH 2-12 media), suitable for humid or chemical environments.

4. Processing performance:

Supports laser cutting, CNC engraving, hot bending and other processes, and the minimum processing radius can reach 2 times the thickness of the plate.

Can be pasted, hot pressed or mechanically fixed, suitable for a variety of installation scenarios.

5. Environmental protection and safety:

RoHS certified, no heavy metals, no halogen, recyclable rate ≥90%.

Flame retardant grade UL94 V-0, self-extinguishing time from fire ≤3 seconds.

Architectural decoration field

Scenario: partition wall, ceiling, light box, background wall.

Solution:

5mm thick frosted board is used for office partition, light-transmitting but not transparent, protecting privacy;

8mm thick board is used for curved ceiling after hot bending to enhance the sense of space design;

Surface hardness ≥2H, scratch resistance is 1.5 times that of ordinary acrylic board, reducing maintenance costs.

Advertising and display industry

Scenario: light box panel, signboard, display rack, window display.

Solution:

Double-sided frosted board improves light transmittance uniformity by 40%, eliminating the "hot spot" phenomenon of light boxes;

Supports UV flatbed printing, color saturation increased by 25%, outdoor weather resistance for more than 3 years;

Lightweight design (density 1.2g/cm³), reducing transportation and installation costs.

Industry and equipment manufacturing

Scenario: equipment protective cover, instrument panel, operating table.

Solution:

10mm thick board has an impact strength of ≥120kJ/m², protecting equipment from collision;

Surface resistivity ≥10¹²Ω, suitable for anti-static environment;

Temperature resistance range -40℃ to 80℃, suitable for extreme climatic conditions.

Furniture and home design

Scenario: cabinet doors, desktops, bathroom partitions, decorative paintings.

Solution:

3mm thick board is used for bathroom cabinet doors, waterproof and mildew-proof, with a service life of ≥10 years;

The frosted surface texture hides fingerprints and water stains, and the cleaning frequency is reduced by 50%;

Special-shaped cutting (such as round and wavy) can be customized to meet personalized design needs.

Transportation and public facilities

Scenarios: subway screen doors, bus stations, airport signs, elevator interiors.

Solution:

The impact resistance of 15mm thick panels has passed the EN 12600 standard to ensure public safety;

The light transmittance is 60%-70%, taking into account both lighting and privacy protection;

No cracks or discoloration after weather resistance testing (1000 hours of UV aging).

Medical and laboratory fields

Scenarios: laboratory tables, instrument housings, isolation covers, clean room partitions.

Solution:

Antibacterial rate ≥ 99% (Escherichia coli, Staphylococcus aureus), in line with medical environmental hygiene standards;

Easy to clean (oily handwriting can be wiped with alcohol), reducing the risk of cross infection;

Resistant to chemical corrosion (no damage from alcohol or disinfectants), suitable for high-frequency cleaning scenarios.

Daily cleaning:

Wipe with a soft cloth dipped in a neutral detergent (pH 6-8), avoiding detergents containing alcohol or solvents.

Oil stains can be treated locally with rosin water, but they need to be rinsed with clean water and wiped dry immediately.

Protective measures:

Avoid scratches with sharp objects. Surface scratches with a depth of ≤0.1mm can be repaired with toothpaste (containing abrasives).

When exposed to ultraviolet light for a long time, reapply UV protective agent every 2 years.

Repair and replacement:

Cracks or breaks require replacement of the entire board, and the interface is sealed with acrylic special glue (shear strength ≥15MPa).

Aged boards (yellowing surface, decreased light transmittance) need to be replaced as a whole to avoid safety hazards.

Storage conditions:

Unused boards should be stored in a dry environment (humidity ≤50%), at a temperature of 5℃-30℃, and avoid direct sunlight.

After opening, they must be used within 6 months, and the remaining parts should be wrapped and sealed with moisture-proof paper.

Q1: Is frosted acrylic board environmentally friendly?

A: It has passed RoHS certification, is free of heavy metals and halogens, and has a recyclability rate of ≥90%.

Q2: Can the size and color be customized?

A: Customization is supported, with a maximum size of 2050mm×3050mm, a thickness of 1.8mm-50mm, and colors produced according to the RAL color card.

Q3: Does light transmittance affect privacy?

A: The light transmittance of single-sided frosted boards is 60%-70%, and the light transmittance of double-sided frosted boards is 40%-50%. Light is not transparent.

Q4: How is the weather resistance?

A: After 5 years of outdoor use, the light transmittance retention rate is ≥85%, and the color difference ΔE≤3.

Q5: How long is the service life?

A: More than 15 years for indoor use and 8-10 years for outdoor use (depending on environmental differences).

From global exhibitions to hands-on demos with top LED brands—our trade show highlights prove why J.K. Optics is the go-to partner for optical diffusion. Browse real-world snapshots of our team in action, showcasing cutting-edge diffuser solutions and collaborating with industry leaders. No hype—just the tangible expertise and innovation we bring to every project.